The Netherlands – Do you have the solution to efficiently use industrial residual heat in the chemical industry? Then Fieldlab Industrial Electrification (FLIE) would love to see you as a pitcher during their side event at the European Industry & Energy Summit (EIES) on December 8th. During this side event FLIE brings industrial supply and demand together.

Practical case on the application of residual heat introduced by Ducor

Chemical company Ducor (Rotterdam) is looking for a more efficient use of their residual heat in order to make a sustainable move. Ducor is a producer of polypropylene granulate. The granulate is produced in three independent extruders from a polymer powder. The granulate is cooled and results in a stream of cooling water (60 0C, 50 kg/s) for every production line, representing total excess heat of about 3,5 MW for the three production lines.

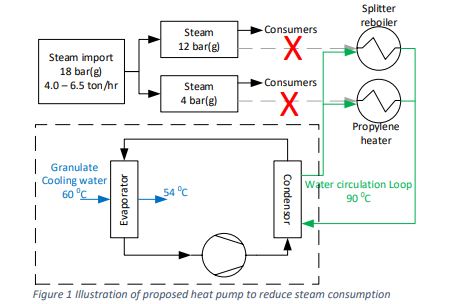

Utilizing part of this energy by a heat pump was investigated in a sustainability study. Steam import of the plant is on average 5.5 ton/hr (range 4 to 6.5 ton/hr) at 18 barg. However, this steam pressure is not required in the plant. Approximately 60% of the steam is consumed at 12 barg, 40% at 4 barg. The sustainability study highlighted the installation of a heat pump to prevent steam usage for a reboiler and propylene heater.

Steam is currently used in the reboiler of a splitter to maintain a recycle stream over the reboiler of 90 0C (duty of 1,4 MW, steam consumption 21 kton/year). Additionally, steam is used in a heat exchanger (steam/glycol) to maintain a glycol recirculation at 66 0C for propylene heating (duty of 0,7 MW, steam consumption 3.1 kton/year). The proposal was to install a heat pump to create a 90 0C water circulation loop by utilizing the excess heat of the granulate cooling water. This water could directly be used in the reboiler of the splitter; the steam/glycol heat exchanger had to be replaced, since the new water circulation loop has a lower temperature than the steam. Problematic was the long payback time of 7 years for the heat pump.

Therefore, would it be possible to lower the investment and/or utilize more of the available excess heat to improve the business case? Fieldlab Industrial Electrification is looking for innovative tech suppliers who have a solution for this. They will have the opportunity to pitch this solution during this matchmaking event on December 8th.