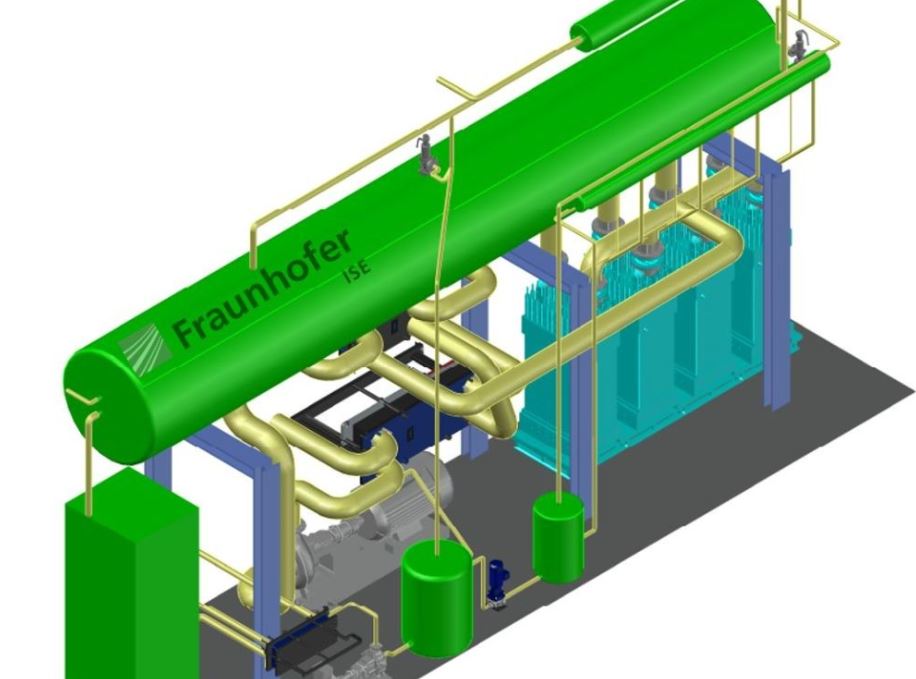

Germany – The “OffsH2ore” project was developed by scientists at the Fraunhofer Institute for Solar Energy Systems ISE as a technical idea and design for a hydrogen generating plant tailored for use at sea.

The objective of the project is to define an economically and technically optimal design for an integrated offshore proton exchange membrane (PEM) electrolysis hydrogen production facility, including the transportation of the compressed hydrogen gas to land.

The OffsH2ore project offers a possible route to a carbon-neutral future by ensuring hydrogen production without territorial competition. The Fraunhofer ISE, PNE AG, SILICA Verfahrenstechnik GmbH, KONGSTEIN GmbH, and Wystrach GmbH are participants in the project, which is supported by the German Federal Ministry for Economic Affairs and Climate Protection.

Offshore wind farm connection

A 500 MW electrolysis station is directly connected to an offshore wind farm that provides the power for the PEM electrolysis. The platform has a yearly production capacity of up to 50,000 tons of green hydrogen. Seawater is desalinated using leftover heat from electrolysis to provide freshwater for the PEM electrolyzer.

A transport vessel that can transport up to 400 tons of hydrogen from the platform to the mainland receives the produced hydrogen after it has been cleaned, dried, and compressed to 500 bar. This idea allows freedom in the selection of locations and is unrelated to the hydrogen transportation pipeline.

The costs

The cost-optimal capacity of the offshore wind farm was established using the electrolysis capacity of 500 MW as a starting point for calculating the costs of hydrogen production. The wind power of 602 MW is responsible for the lowest hydrogen production prices. They total 5.92 EUR/kg in this instance with just about 5,000 full charge hours of electrolysis.

Lower wind capacity results in higher costs for hydrogen generation and fewer full charge hours. For instance, a wind farm with a capacity of 490 MW results in full load hours of about 4,225 h/a and hydrogen production costs of €6.37 ($7.04)/kg. The 500 MW electrolysis is significantly larger and can no longer run at a nominal load because to the decreasing wind capacity.

Carbon-neutral future

By combining offshore wind energy and saltwater as resources for hydrogen synthesis, this initiative offers a possible route to a carbon-neutral future. The idea assures hydrogen production without territorial competition and gives location choice flexibility. The initiative provides a sneak preview of offshore hydrogen production’s potential and its contribution to the decarbonization of the energy industry.