Norway – Joint venture Northvolt–Hydro for battery recycling In Fredrikstad, southern Norway, Hydrovolt has started commercial recycling operations.

Hydrovolt is Europe’s largest electric vehicle battery recycling plant, with a capacity of 12,000 tons of battery packs processed per year. With the plant now operational, a long-term solution for handling Norway’s entire volume of electric vehicle batteries that are being phased out or reaching the end of their useful lives is now available.

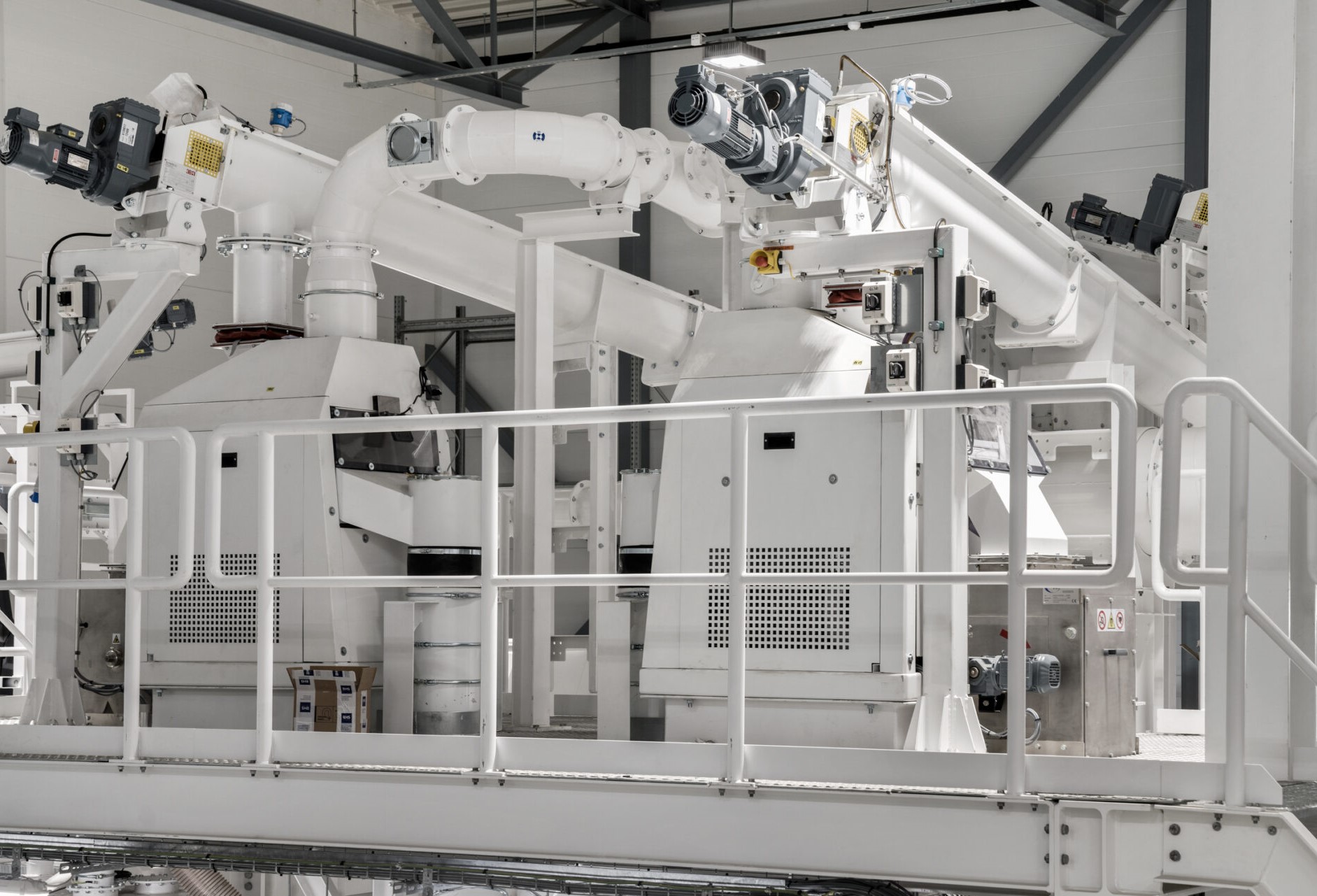

Hydrovolt can recover and isolate 95% of the materials in a battery, including plastics, copper, aluminum, and black mass, thanks to a novel process design. Within the plant, there are several novel concepts designed to maximize material recovery, including a dust collection system that ensures valuable material lost during mechanical recycling steps is captured.

Expanding recycling in Europe

Hydrovolt is looking into expanding its recycling capacity in Europe, with a long-term goal of recycling 70,000 tons of battery packs by 2025 and 300,000 tons by 2030, which equates to about 150,000 electric vehicle batteries in 2025 and 500,000 in 2030.

Battery recycling will directly contribute to the battery industry’s long-term viability and is required to comply with emerging European battery regulations, including upcoming mandatory recycling targets.

Significantly, the recovery of black mass – a powder containing nickel, manganese, cobalt, and lithium – will reduce today’s reliance on mining as a source of primary raw materials, as well as all the associated risks and vulnerabilities. A hydrometallurgical treatment, such as the one being developed at Northvolt’s Revolt Ett recycling plant in Skellefte, Sweden, is required to convert black mass into battery-grade material. Hydrovolt is expected to produce over 2,000 tonnes of black mass per year by 2025.