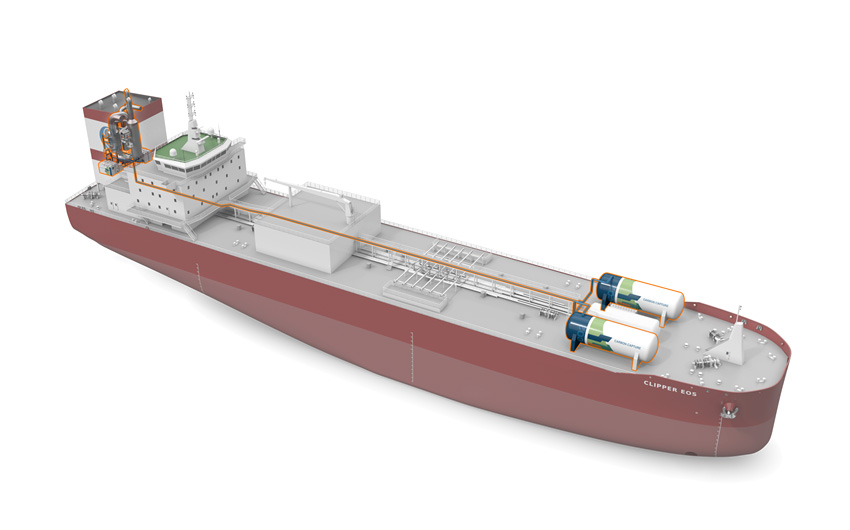

Norway – Wärtsilä Exhaust Treatment and Norwegian shipping operator Solvang have agreed to install a full-scale pilot retrofit carbon capture and storage (CCS) system aboard one of Solvang’s ethylene carriers, the 21,000-cbm Clipper Eos.

Wärtsilä Exhaust Treatment creates the retrofitting unit while also finishing a 1MW land-based test system at its Moss headquarters in Norway. The land-based unit is expected to be completed in autumn 2021, while the pilot CCS system on the Clipper Eos is expected to be retrofitted by 2023.

The collaboration boosts Wärtsilä’s ongoing research and development into carbon capture at the point of exhaust, which will aid the maritime industry’s decarbonization efforts.

The initiative will allow both Wärtsilä and Solvang to improve their positions at the forefront of sustainable shipping technology development. To meet the IMO’s decarbonisation requirements, Wärtsilä’s pilot unit will first aim for a 70% decrease in CO2 emissions at the point of exhaust.

Since its delivery from the shipyard in 2019, the vessel, Clipper Eos, has been time chartered by Marubeni Corp., Tokyo. Marubeni, which has more than 40 years of trading and handling ethylene, said it is committed to working with Solvang and Wärtsilä to complete required testing and installation of technology on the vessel in a joint effort to dramatically reduce the vessel’s CO2 footprint.

Wärtsilä recently announced a partnership with the LINCCS consortium to scale and produce carbon capture technologies and infrastructure, in addition to signing a Letter of Intent with Solvang and scaling its Moss CCS test unit. The partnership recently won funds for CCS research and development totaling 111 million Norwegian Kroner.