Germany – The Salzgitter Group has chosen Andritz as the supplier of one of Europe’s largest green hydrogen reactors for the Salcos program, which aims to produce essentially CO2-free (green) steel production.

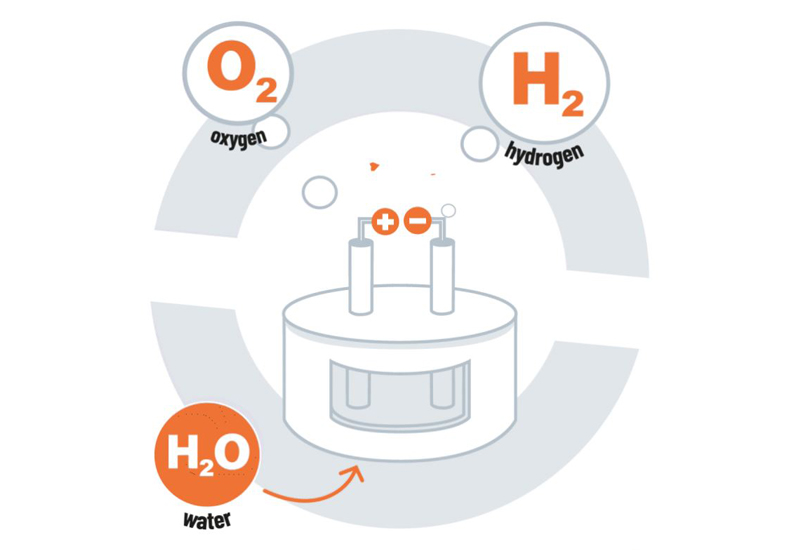

At the Salzgitter Flachstahl GmbH site, Andritz will construct a 100 MW electrolysis plant using HydrogenPro’s pressurized alkaline electrolyzer technology on an EPC basis. In order to make green steel, the plant will start producing about 9,000 tons of green hydrogen annually in 2026. With this, the SALCOS program’s industrial use of hydrogen will officially begin.

Salcos program

Three steps will be taken to complete the Salcos program. The 100 MW electrolysis plant for producing green hydrogen will be part of the first stage, which would be operational as early as 2026. It will also include a direct reduction plant and an electric arc furnace, both of which had already been ordered. By the end of 2033, well in advance of the legal requirements, the Salzgitter facility will have converted to a nearly CO2-free steel production process.

Salcos’ stage 1 financing has been secured thanks to grants from the Federal Republic of Germany and the State of Lower Saxony as well as a sizeable contribution from Salzgitter AG.