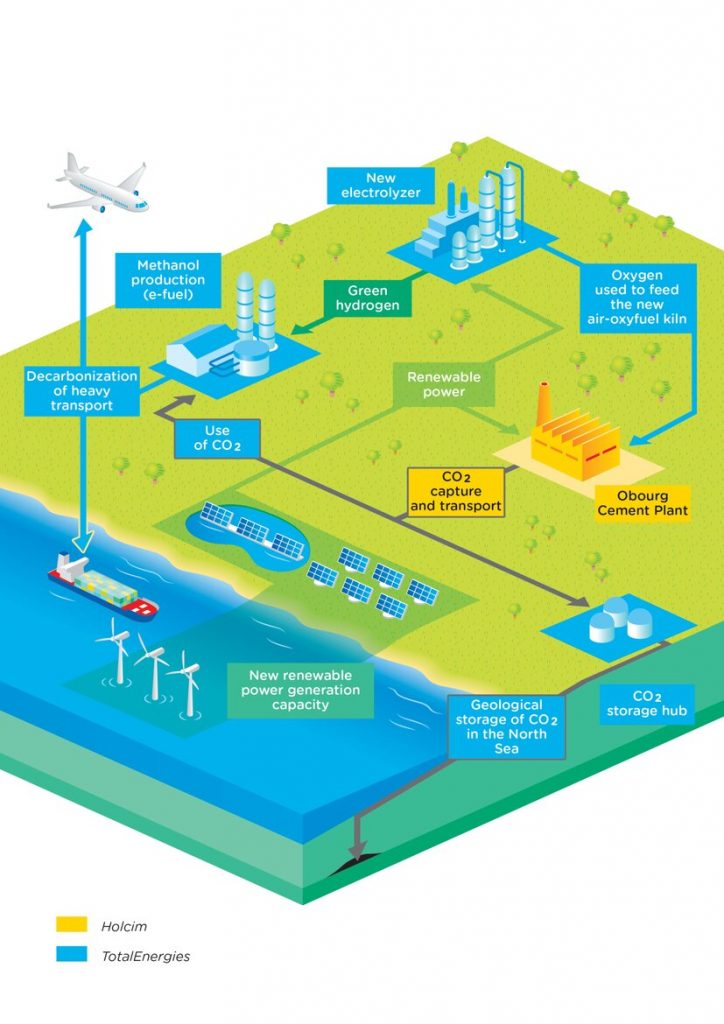

Belgium – TotalEnergies and Holcim will together endeavor to completely decarbonize a Holcim-upgraded cement manufacturing facility in Obourg, Belgium.

For the effective capture, use, and sequestration (CCUS) of the roughly 1.3 million metric tons of CO2 the facility emits each year, several fuels and technologies will be evaluated.

Renewable projects

As part of Holcim’s renovation of the current cement plant, each partner will provide its best-in-class technology, including a cutting-edge new air-oxyfuel switchable kiln to make it easier to capture and purify CO2 in the flue gases. They will also involve TotalEnergies’ transportation and use of the captured CO2 for a novel e-fuel production plan, as well as the deposit of that CO2 in geological storage in the North Sea.

To power a new electrolyzer that would produce the green hydrogen necessary to create e-fuels, TotalEnergies will evaluate the development of renewable projects. In addition to powering Holcim’s new oxyfuel kiln, this increased capability for producing renewable energy will aid in the decarbonization of the cement plant. Finally, the new kiln would be fueled by the oxygen released by the electrolyzer.