United Kingdom – Fugro-led consortium that includes AS Mosley and the University of Strathclyde has developed a mooring line fatigue tracker that safely and cost-effectively monitors offshore floating wind turbines.

The tracker was created with the help of Scottish Government innovation funds. The consortium won funding to develop the tracker, which fuses motion and position measurements of floating hulls with a simulation model to monitor fatigue, in March 2020 through the Carbon Trust’s Floating Wind Joint Industry Project’s Floating Offshore Wind Technology Acceleration Competition (FLW TAC). Fugro and partners are now looking for chances to cooperate with floating wind developers on pre-commercial projects to test the solution offshore, having already demonstrated the technology in a relevant setting.

Reducing in-person inspections

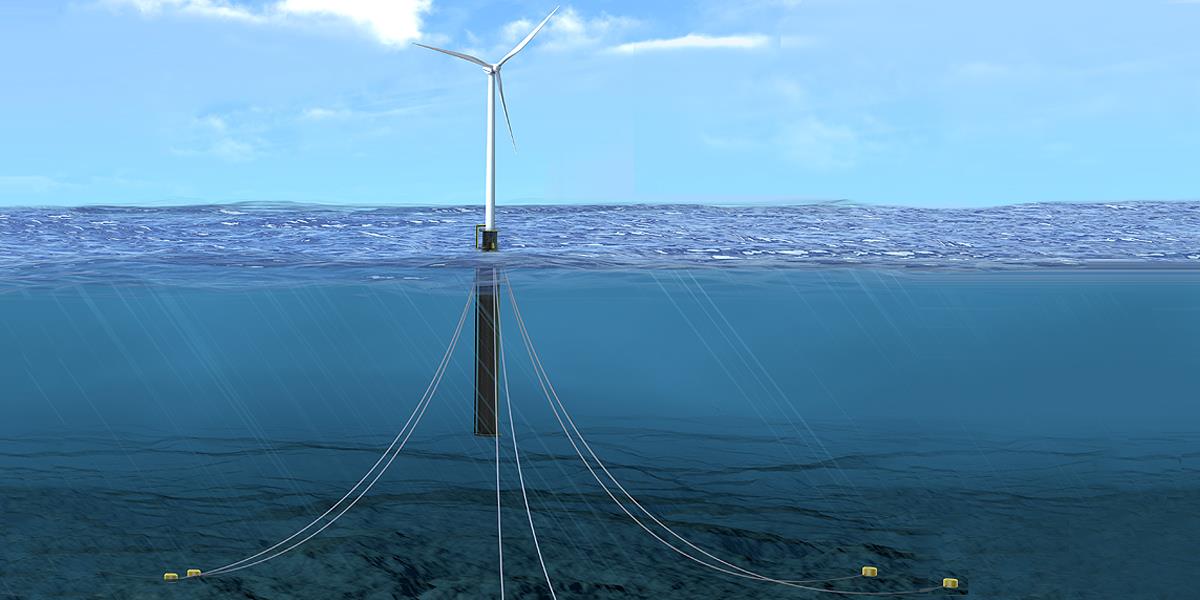

Floating offshore wind farms will need to run reliably and reduce in-person inspections to reduce HSSE risk exposure and remain cost-effective as a future element of the UK’s green energy producing portfolio. Fugro collaborated with AS Mosley and the University of Strathclyde to establish a cost-effective and streamlined methodology using their existing satellite location, structural, and metocean monitoring systems. Instead of the existing 5-year subsea inspection schedule, mooring line fatigue will be monitored, allowing inspection activities – which require vessels and remotely operated vehicles (ROVs) – to be carried out only when absolutely necessary. Another advantage is that the monitoring is continuous, allowing for early detection of any issues or failure situations, such as anchor drag or trawler snagging.