Location matters. So does type of business. Political circumstances certainly do. And what about geopolitical conditions? Transition, moreover, needs passionate people. In the first week of our Hydrogen Trail Europe (HYTE), we learned a lot. Especially about the different choices that different companies make in different locations with a variety of conditions.

In Rotterdam, companies want to transform the existing system from the inside. And particularly at the front end. It will be giant steps if the enormous amounts of hydrogen already used in refineries and chemical plants can be produced without CO2 emissions to the air.

The arrival of 1 gigawatt of green hydrogen plants at the Maasvlakte, where 7.5 gigawatts of offshore wind power will come ashore by the end of the decade, seems logical. And so does the fact that various parties at the port are investing in green ammonia terminals. Ammonia seems to be in pole position as a carrier of hydrogen, for overseas transport. Just another liquid? Will ammonia eventually supplant petroleum?

Junction

In the north of the Netherlands, there seems to be plenty of room for new industry and new processes. In the Eemshaven and also in Delfzijl. The Chemie Park Delfzijl, for example, is to undergo substantial expansion. There is also room in the new section for hydrogen production. HyCC and Gasunie already have plans for both the old and the new site.

Potential customers include BioMCN. That can bind hydrogen to CO2, to make sustainable methanol from it. The company is already doing this with a residual flow of hydrogen. Will this eventually replace its natural gas feedstock completely? Perhaps it will provide more stability than natural gas, with all its vagaries. Completely new in the Northern Netherlands is the planned production of aviation fuels from CO2 and hydrogen.

Moreover, the Northern Netherlands has a great location with regard to the energy infrastructure. Large amounts of electricity already come ashore and new offshore wind farms can be connected there.

And it is also a hub of the natural gas transport network. Parts of the grid can be converted for hydrogen transport. And there’s more. A stone’s throw away from the Eems Delta, in Zuidwending, there are also empty salt caverns, which can store gases due to the density of the salt on the inside. Including hydrogen. Location does matter.

It takes six to tango

A bit further across the border, Uniper in Wilhelmshaven is working on a total make over. The coal plant has already been shut down and it is planned to demolish the enormous chimney. The huge grassy areas around the power plant already have a new use. There are plans for 1 gigawatt (!) of green hydrogen production. And closer to the coast an ammonia terminal is to be built. If it is up to Uniper, Wilhelmshaven will become Germany’s first major hydrogen hub. In addition to being an energy supplier, the company will also soon be a supplier of building blocks for industry. For example, for the greening of Salzgitter’s steel production.

Even more than for other parties, cooperation is enormously important for a supplier of energy and raw materials. It takes six to tango. Governments, transporters – of electricity, hydrogen and ammonia -, new customers, society, suppliers of new technology and of course the companies themselves. There does seem to be more urgency, however, due to the current crises, which means that the noses are somewhat more in the same direction.

And German companies seem helped by a new LNG law, which came into force just after the outbreak of the war in Ukraine. As a result, projects that could reduce dependence on Russian gas can count on a simplified and faster permitting process.

Heavier road traffic

For smaller plants, such as the hydrogen projects realized so far, fewer permits are needed in Germany anyway. We also heard this from Shell Rheinland in Wesseling, Germany. There the group has a hydrogen electrolyzer with a capacity of 10 megawatts. Until recently it was Europe’s largest. A further 100 megawatts are to be added soon.

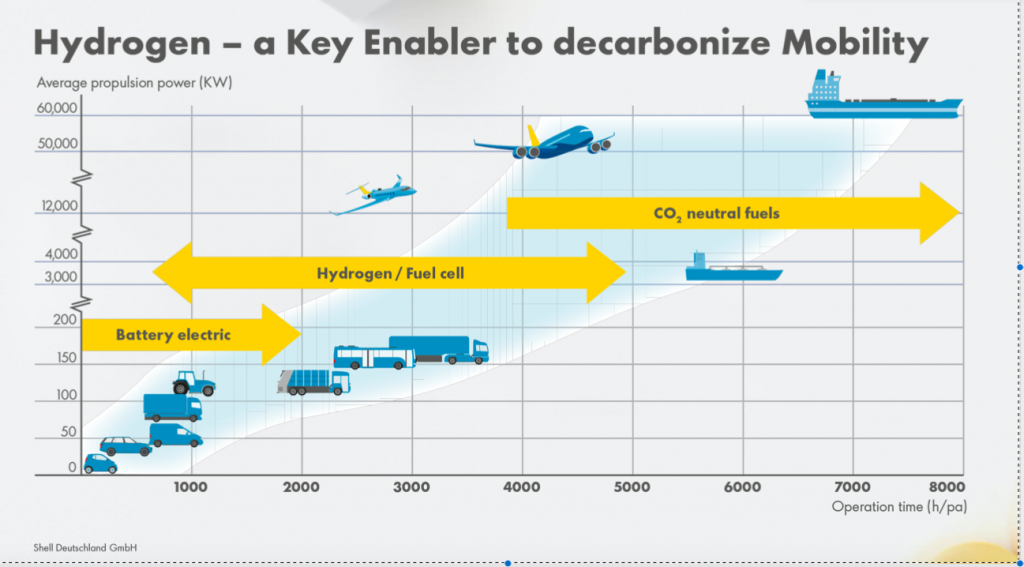

At Shell everything seems to be focused on the future of fuels. Much of the drive will be electric. The only question is how we are going to transport the energy we need. Batteries and passenger cars seem to be the best combination. Small trucks are also heading in that direction. According to Shell – which, incidentally, is also active in electric charging stations – the area of hydrogen will soon begin with heavier road traffic. And think also of smaller aircraft. For larger aircraft and international shipping, Shell is focusing on liquid (bio)fuels.

Turquoise route

The perspective of chemical giant BASF is different again. That company sees hydrogen primarily as an interesting building block for various chemical processes. Exactly what the future will look like remains unclear, of course. But the current crises do call for the development of sufficient alternatives. Germany, more than some other countries, is facing up to the facts. Betting on a horse is no longer wise.

Very interesting at BASF is the development of methane pyrolysis, or the turquoise route to produce hydrogen. Methane (natural gas or biogas) is the feedstock, but there are no CO2 emissions. It does produce pure carbon. Purer than carbon black, BASF’s experts argue. In the chemical giant’s process, carbon powder falls down into the reactor, binding other carbon particles along the way.

A test installation stands in the middle of BASF’s enormous grounds in Ludwigshafen. It will be several years before a commercial plant is built. If the investment decision were made now, it could easily be in the US, where BASF also has large sites. After all, the price of natural gas in the U.S. is still stably low. Of course, sufficient affordable green electricity would have to be available, as well as a good infrastructure for the purchase of hydrogen and pure carbon. Again: location matters!

Mountain landscape

In Switzerland, there are entirely different opportunities and challenges. In Niedergösgen, we visited an Alpiq hydroelectric plant that is more than 100 years old. Industrial heritage! From part of the hydroelectric power, the joint venture Hydrospider makes hydrogen with a 2 megawatt electrolyzer. Switzerland, partly motivated by its mountainous landscape, has hardly any gas infrastructure. The hydrogen gas produced by the company is therefore transported to filling stations by container. Hydrospider focuses on heavy transport. There are currently 46 Hyundai trucks on the road, and hundreds more are expected in the coming years. It is also the intention that green hydrogen will be produced at various locations.

The choice for freight transport also seems to be dictated by the geographical location. Switzerland has little heavy industry anyway. Moreover, the mountainous landscape is less suitable for electric trucks with enormous weights of heavy batteries. It is the situation…