Finland – Wärtsilä is part of a consortium that has obtained financing from the European Union to study strategies for reducing methane slip from marine engines and promoting the environmental and climatic advantages of LNG as a ship fuel.

The Finnish Meteorological Institute, shipyard Chantiers de l’Atlantique, ship owner CMA CGA, classification society DNV GL, non-profit organization Revolve Water, and energy giant Shell are among the organizations participating in the Green Ray project, which is being coordinated by VTT Technical Research Centre of Finland.

The project will create unique aftertreatment ideas as well as on-engine technology for 2- and 4-stroke low-pressure dual-fuel engines. These solutions, which will include demonstrators installed on two newbuilds and one adapted to an existing vessel, will be developed to a high state of technological readiness. The entire suite of Green Ray technologies will also be fully capable of using bio- or synthetic methane in place of fossil LNG.

Wärtsilä technology

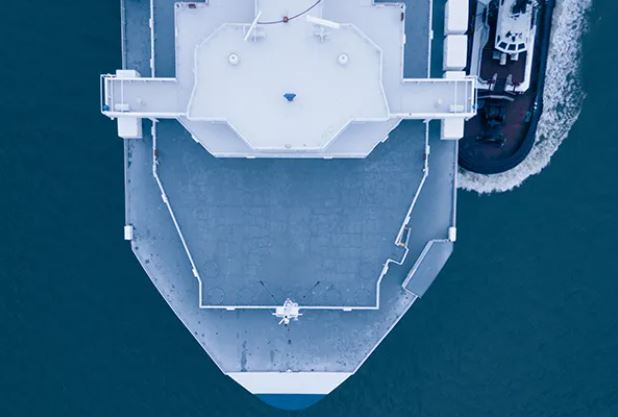

Wärtsilä will create technology specifically for low pressure 4-stroke dual fuel engines that reduces methane slip, boosts efficiency, and costs less to operate at all engine loads. This technique targets the biggest four-stroke engines currently available, which are frequently utilized by ferries, LNG carriers, and cruise ships.

In order to lessen methane leakage from tankers, container ships, etc., Wärtsilä will also develop an on-engine technology for 2-stroke engines based on a patented LNG injection system. Throughout the project, both technologies will be put to the test in a live setting at sea in cooperation with the Green Ray partners.

LNG as maritime fuel

A well-established supply infrastructure, a clear shift to cleaner fuels, and considerable reductions in air pollution and climate benefits are all driving up the use of LNG as a maritime fuel. One of the biggest obstacles to further adoption is the problem of methane slip, which is the unburned and consequently unutilized fuel that leaks into the atmosphere from engines and throughout the production and supply chain.

Shell has created a proprietary methane abatement catalyst system that has been scaled up for a field demonstration and tested in the lab. This system was found to be effective in handling common compounds that can degrade the catalyst by including a guard bed, in addition to significantly reducing methane slip (over 90%).

Through Horizon Europe, the project has received funds totaling about €7 million. The duration is 2027.