The Netherlands – The decentralized and scalable production of bio-LNG as part of the FirstBio2Shipping project will aid in the decarbonization of maritime transportation. Bio-LNG (liquid biomethane) will be produced at the Attero facility in Wilp, the Netherlands, when the plant is completed in 2023.

Bio-LNG will play an important role in the EU’s efforts to decarbonize the maritime industry and accelerate the transition to a renewable energy source. A strong pathway to maritime decarbonization through bio-LNG has been demonstrated by the collaboration of the leaders in sustainable fuels. Fit for 55 funding has recognized the FirstBio2Shipping project as practical because it will be able to supply existing LNG fuelling infrastructure.

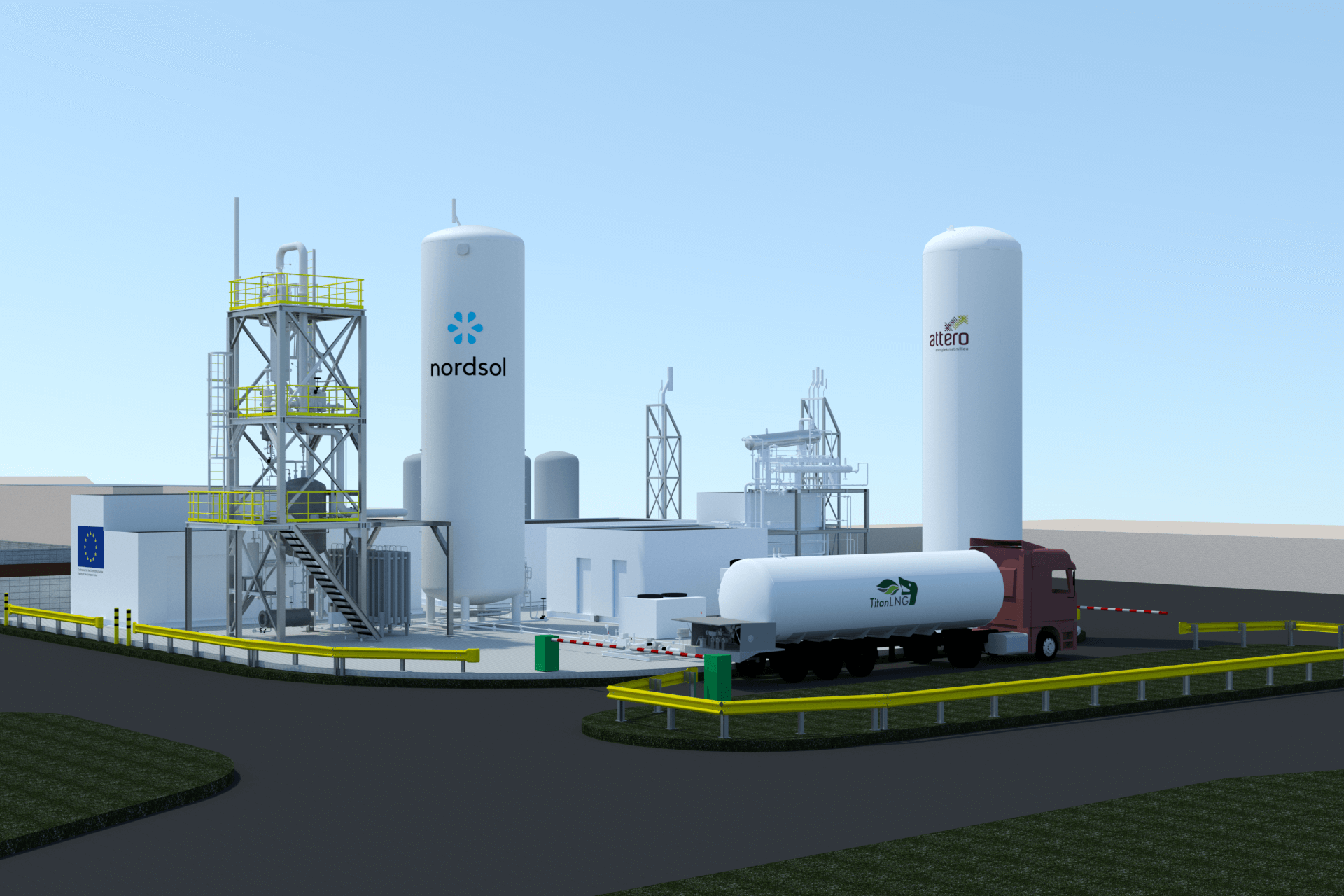

In order to produce Bio-LNG, organic waste flows are used, particularly domestic and agricultural waste. The FirstBio2Shipping project will generate 6 million Nm3 of biogas annually from domestic biowaste. Nordsol’s iLNG technology transforms biogas into bio-LNG by upgrading and liquefying it. As a result of this technology, small-scale LNG can be produced without the presence of contaminants, with zero methane “slip,” and without the need for high temperatures in gas treatment technologies, resulting in a lower total cost of ownership for the owner.

To meet the growing demand for liquid bio-CO2, Attero and Nordsol have joined forces to produce 2,400 tons of high-purity bio-LNG annually and 5,000 tons. In order to save money, Titan, the exclusive long-term offtaker, will supply bio-LNG to the maritime industry. More than 87500 tCO2e net absolute emissions will be avoided during the first ten years of operation thanks to the 92% reduction in GHG emissions that bio-LNG will provide compared to conventional maritime fuel.

While it may not be net-zero in GHG emissions, it could be net-negative by substituting fossil CO2 with bio-CO2 liquefied from waste streams. This is consistent with the sustainable circular model in which waste streams are digested and bio-LNG is produced from them.

The introduction of this first bio-LNG plant for shipping means that LNG-powered vessels can take a significant step toward achieving decarbonization goals and meeting EU and IHO regulations. Titan, Attero, and Nordsol’s bio-LNG production will continue to grow, and the shipping industry’s path to decarbonization via LNG, bio-LNG, and E-LNG is well underway.