United States – Topsoe, a Danish business specializing in carbon emission reduction solutions, and ExxonMobil, a US energy and petrochemical company, have agreed to deploy Topsoe’s hydrogen SynCOR technology to ExxonMobil’s planned low-carbon hydrogen production facility in Baytown, Texas.

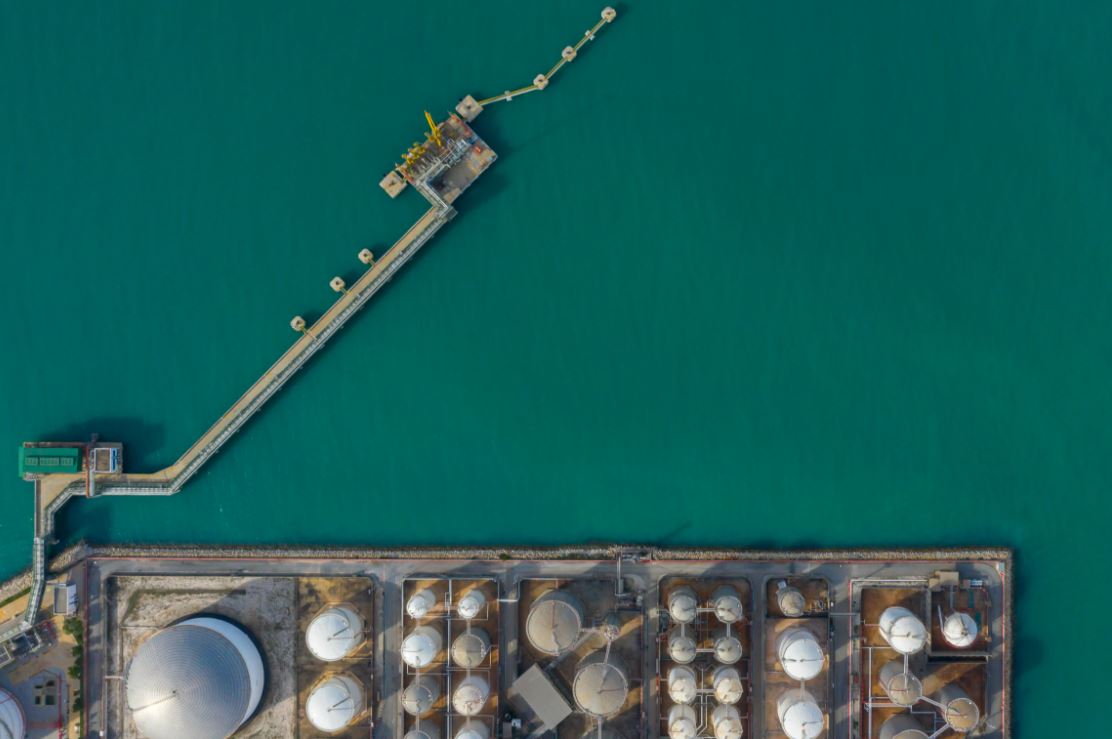

The facility, which will be built at ExxonMobil’s integrated refining and petrochemical complex in Baytown, Houston, Texas, is designed to produce 1 billion cubic feet of hydrogen per day, making it the world’s largest low-carbon hydrogen project when it opens in 2027-2028.

Topsoe claims that its SynCOR hydrogen technology will enable ExxonMobil to manufacture hydrogen on a massive scale while also capturing and storing more than 98% of its associated CO2 emissions, or around 7 million metric tonnes per year.

SynCOR is a technique that is based on advanced auto thermal reforming principles, and it is often the favored technology for mega-scale hydrogen generation due to its maturity and cheap capital and operating costs, according to Topsoe.

Carbon capture integration

Topsoe has partnered with Honeywell UOP, a carbon capture technology licensor, to create an integrated solution for the Baytown complex. Honeywell UOP will provide its carbon capture technology for the site.

The project will supply low-carbon fuel to the Baytown olefins plant and other Houston-area industries. It is worth noting that substituting natural gas with hydrogen at the Baytown olefins factory might lower CO2 emissions by up to 30%.