United States – An approach to converting an unwelcome byproduct into cash has been discovered by engineers and scientists at Rice University for petrochemical refineries.

Hydrogen sulfide gas has an unmistakable stench of rotting eggs. As a byproduct of procedures that remove sulfur from petroleum, natural gas, coal, and other goods, thousands of tons of the hazardous gas are created every year. It typically comes from stockyards, landfills, and sewers, but it is particularly troublesome for petrochemical factories, refineries, and other sectors.

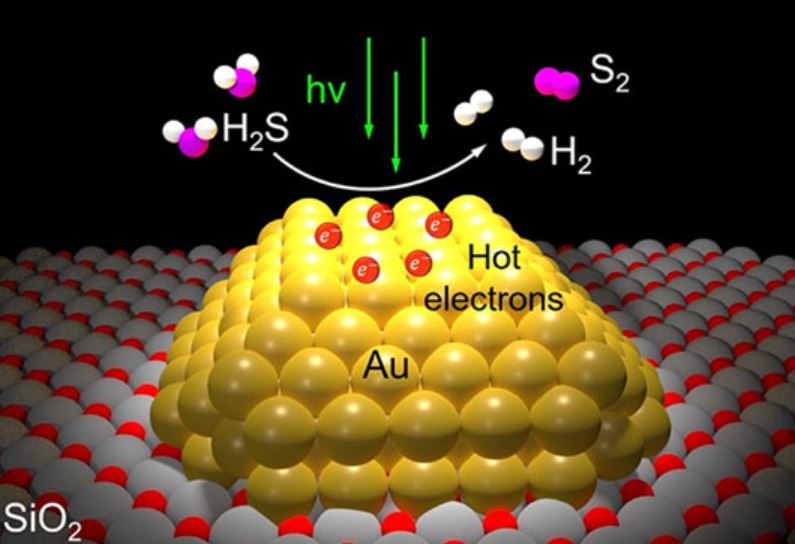

In a single step, a method developed by Rice engineer, physicist, and chemist Naomi Halas and colleagues converts hydrogen sulfide into sulfur and highly useful hydrogen gas. The one-step method is even better because it simply requires light as a source of energy. The study’s co-authors are Hossein Robatjazi of Syzygy Plasmonics, Emily Carter of Princeton University, and Peter Nordlander of Rice University.

“Hot carriers”

Two hydrogen atoms and one sulfur atom make up each hydrogen sulfide gas molecule (H2S). Clean-burning hydrogen gas (H2), which makes up the majority of the hydrogen economy, has two hydrogen atoms in each of its molecules. In the most recent study, Halas’ team deposited minuscule islands of gold on silicon dioxide powder grains. Each island was a gold nanoparticle 10 billionths of a meter wide that interacted strongly with a certain wavelength of visible light. These plasmonic events result in “hot carriers,” or short, high-energy electrons, which can fuel catalysis.

In the study, Halas and co-authors showed how hot carrier photocatalysis could be efficiently induced by a bank of LED lights in a lab setting, converting H2S directly into H2 gas and sulfur. It is stunning when compared to the well-known catalytic method refineries use to break down hydrogen sulfide. It is known as the Claus process and converts sulfur into water rather than hydrogen. The Claus technique includes a number of phases, some of which require heating combustion chambers to a temperature of about 1,500 degrees Fahrenheit.

Syzygy Plasmonics, a Houston-based startup company with more than 60 employees that has licensed the plasmonic hydrogen sulfide remediation technology, was founded by Halas and Nordlander.