The Netherlands – The climate issue calls for other chemical pathways. Plasma, for example. Together with electrical cracking, a plasma reactor could soon provide a double blow. Methane from the cracking process will no longer be burned, but converted into additional chemical building blocks. On June 5, the Electro Trail Europe starts at the plasma laboratory of Brightsite at Chemelot.

Currently, much attention is focused on green hydrogen, or the electrolysis of water that creates hydrogen and oxygen. According to project manager Hans Linden (TNO/Brightsite) and Professor Gerard van Rooij (Maastricht University), it is highly questionable whether this is an effective way to use – as yet – scarce green generated electricity in the Netherlands.

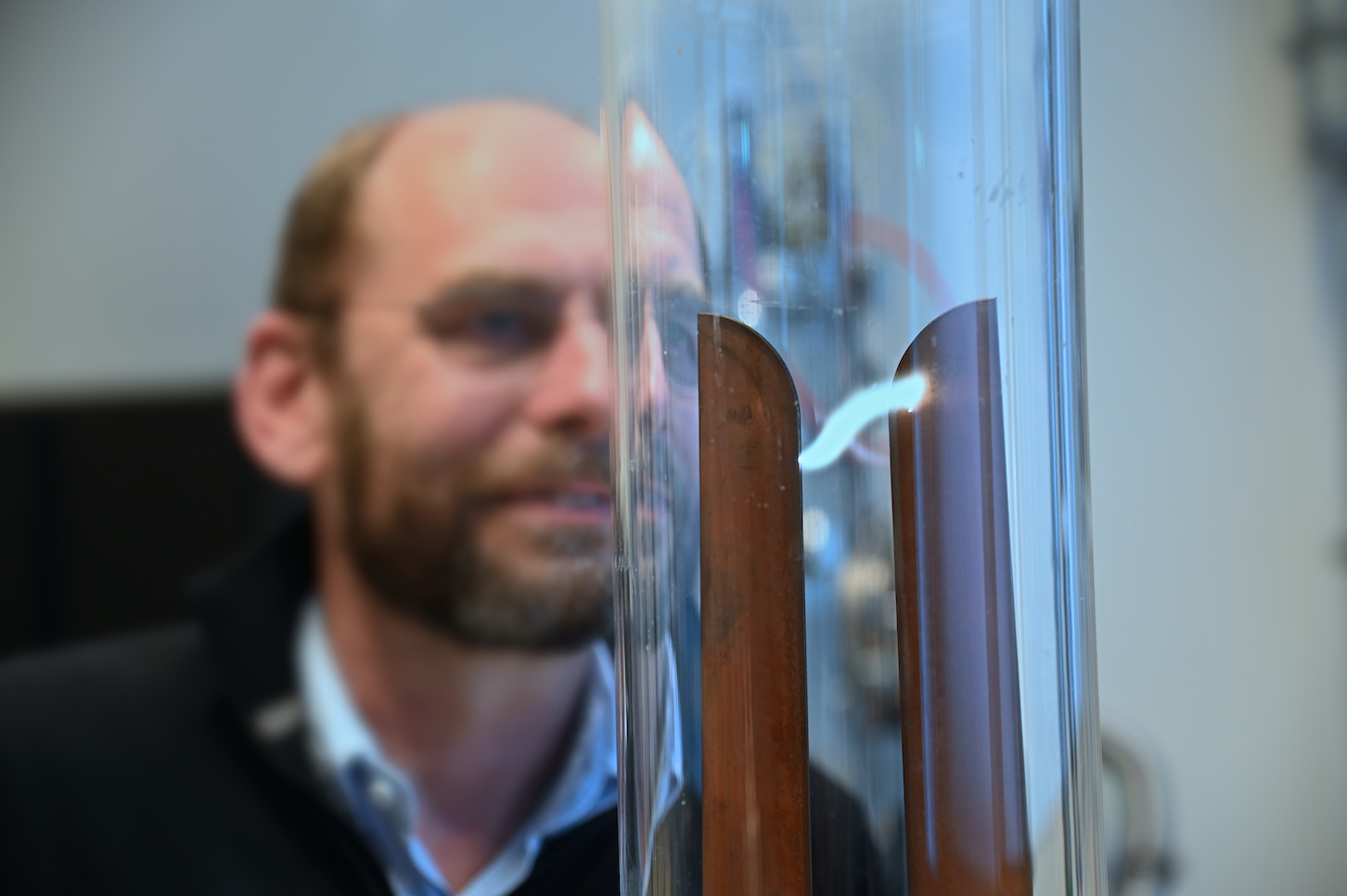

In the plasma laboratory of Brightsite at Chemelot, for example, research is being carried out into how plasma technology can be used to produce acetylene or ethylene from methane in combination with hydrogen efficiently and soon affordably. Linden: ‘We have taken the first steps with acetylene. We now have plans in that area for the construction of a serious pilot plant in Geleen, think of dimensions of about ten by fifteen meters. The big challenge for now is to make this route affordable.’

Dubbed

Initially, Brightsite’s plasma lab is primarily looking at application of the technology at companies at Chemelot. Linden: ‘What are the possibilities, what technology do we need? And various feedstocks and end products are being considered, not to mention safety and social acceptance. If we want to make large industrial projects possible, everything has to be ready on time. Similarly, new equipment must be developed.’

Moreover, with its special focus on the conversion of methane into ethylene or acetylene, the plasma lab seems to anticipate other developments in the transformation of chemistry. Gerard van Rooij: ‘Electric cracking is getting a lot of attention at the moment. A lot of methane is produced in the cracking process. In traditional crackers, the methane is burned to provide energy for the cracking process. This creates the enormous CO2 emissions. In electric squatting, the energy will soon be supplied by green generated electricity. But large amounts of methane are still produced. If we soon succeed in converting that methane via plasma processes into additional ethylene or other chemical building blocks, you will make a double whammy in the chain.’

Electro Trail Europe (Electe23)

From June 5th to 16th, Industryandenergy.eu and VoltaChem will join a group of students and young professionals to visit several innovative electrification and electrochemical projects in European industry. Several vlogs and blogs will be made along the way. By train, the group will go from the plasma lab at Chemelot to BASF Ludwigshafen in Germany, among other places, to witness a pilot electric cracker.

In the second week, the group goes to Örnsköldsvik, Sweden, among other places, where Ørsted, together with Liquid Wind, is building a large plant on the Övik site for the electrochemical production of fuel from CO2 and hydrogen, eMethanol. In Copenhagen, the Trail concludes with several visits, including to the Solid Oxide Electrolysis Cell test center of technology developer Topsoe.

Follow the blogs and vlogs on the Linkedin page Electro Trail Europe (Electe23).