The Netherlands/Poland – Teijin Aramid teamed up with Clariter to develop a long-term chemical advanced recycling solution for Endumax, an ultra-high molecular weight polyethylene (UHMW-PE).

The companies will work together to develop a long-term solution for highly valuable, post-production, and end-of-life materials that are difficult to recycle mechanically.

Teijin Aramid has been looking for a long-term solution for recycling end-products as a forward-thinking company. Clariter’s cutting-edge technology converts potentially hazardous plastic waste into high-value, pure industrial products with a net negative carbon footprint, meaning it cleans rather than pollutes the environment.

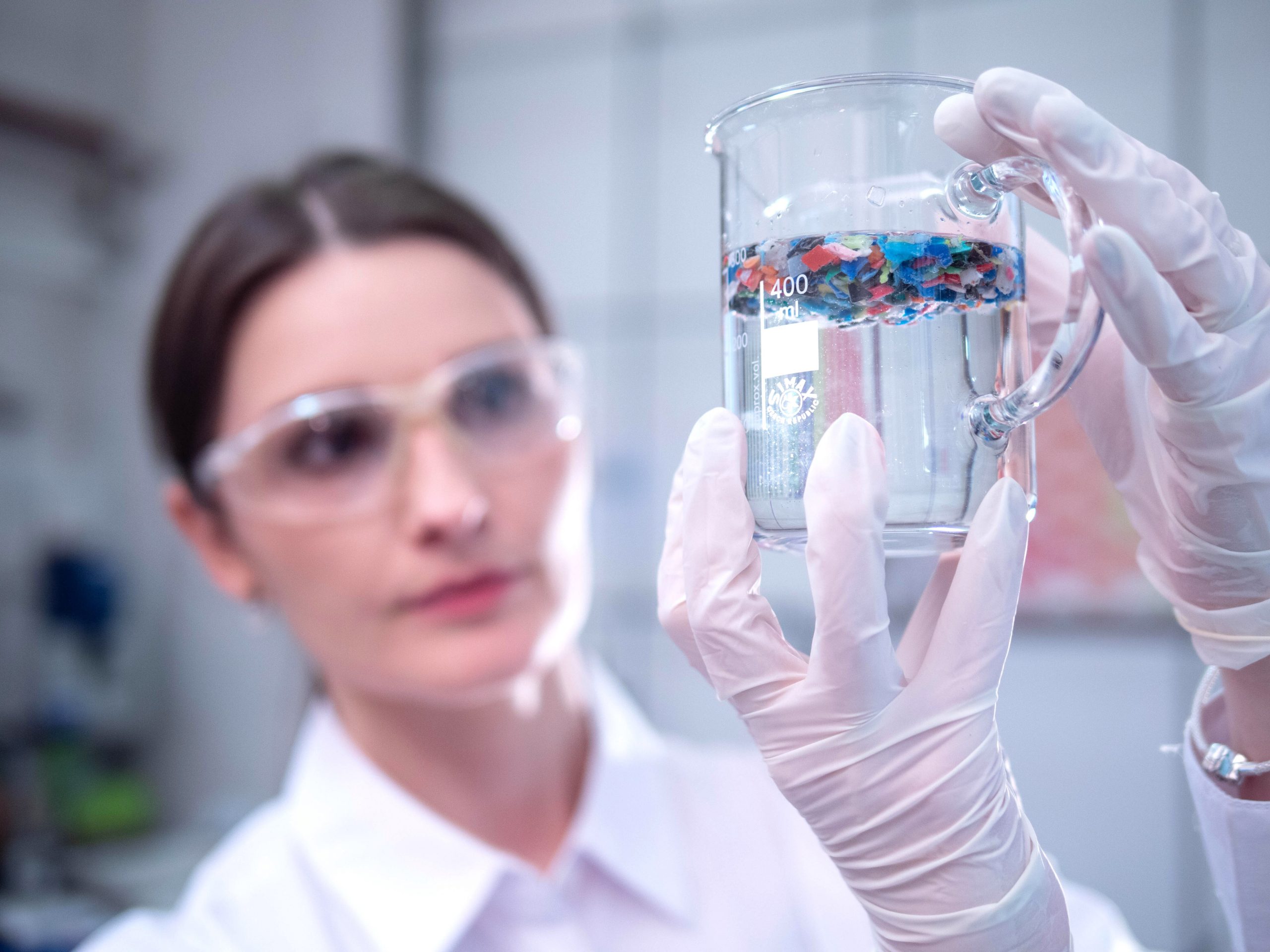

At Clariter’s operational Pilot Plant in Gliwice, Poland, tests of Teijin Aramid’s Ultra-High Molecular Weight Polyethylene (Endumax) feedstock were conducted. The findings showed that fishing nets, ropes, and air cargo containers are all suitable for chemical recycling. UHMW-PE, which was once difficult to recycle, has now been successfully upcycled into feedstock as pure, crude-free industrial products with thousands of uses, including cleaning agents, degreasers, paints, and specialty waxes.

For some markets, such as fishing nets, this results in complete circularity because the wax can be used to coat fishing nets again; for others, this open loop recycling results in valuable products that can be used in manufacturing processes or in other applications.