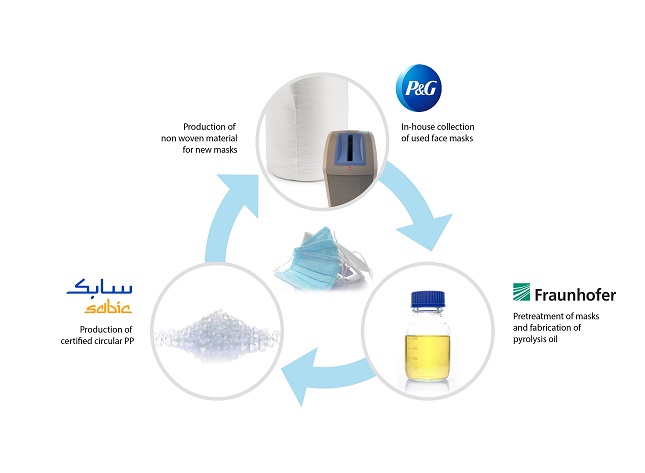

Germany – Fraunhofer Institute UMSICHT, SABIC, and Procter & Gamble (P&G) have joined forces in an innovative circular economy pilot project to demonstrate the viability of closed-loop recycling of single-use face masks.

Because of COVID-19, the use of billions of disposable face masks is causing environmental problems, particularly when they are abandoned in public places such as parks, open-air venues, and beaches. Aside from the problem of dealing with such large volumes of important personal healthcare goods in a sustainable manner, simply discarding used masks for disposal on landfill sites or incineration facilities means a waste of precious feedstock for new material.

Efficient recycling at P&G

P&G collected used face masks used by employees or given to visitors at its production and research sites in Germany as part of the trial. Although such masks are usually disposed of responsibly, there was no ideal recycling route in place. Special collecting bins were set up to help demonstrate a potential step shift in this scenario, and the collected used masks were shipped to Fraunhofer for further processing in a specialized research pyrolysis unit.

SABIC uses pyrolysis oil as feedstock

The pyrolysis oil was then delivered to SABIC for use as feedstock in the manufacture of fresh PP resin. The resins were created by combining alternative feedstock with fossil-based feedstock in the manufacturing process, which is a widely accepted principle. Mass balancing is regarded as a critical link between today’s large-scale linear economy factories and the more sustainable circular economy of the future, which is now operating on a smaller scale but is predicted to expand rapidly.

PP polymer goes into fibers

Finally, the PP polymer was sent to P&G, where it was processed into non-woven fibers material. The complete closed loop pilot project, from facemask collection through production, took only seven months to develop and implement. Fraunhofer CCPE is investigating the applicability of advanced recycling to additional feedstocks and chemical products.