United States – Scientists from LanzaTech, Northwestern University, and the Department of Energy’s Oak Ridge National Laboratory have come up with a way to capture carbon dioxide from industrial processes and use it to make acetone and isopropanol, which is also called IPA.

Uses tiny but powerful factories called microorganisms to turn carbon from agricultural, industrial and societal waste into chemicals that can be used to make things like food and medicine. The process reuses carbon that would otherwise be released into the air as greenhouse gases that speed up climate change. An example of this technology is that it helps move us closer to a “circular carbon economy,” where products made from renewable resources are used to make new ones.

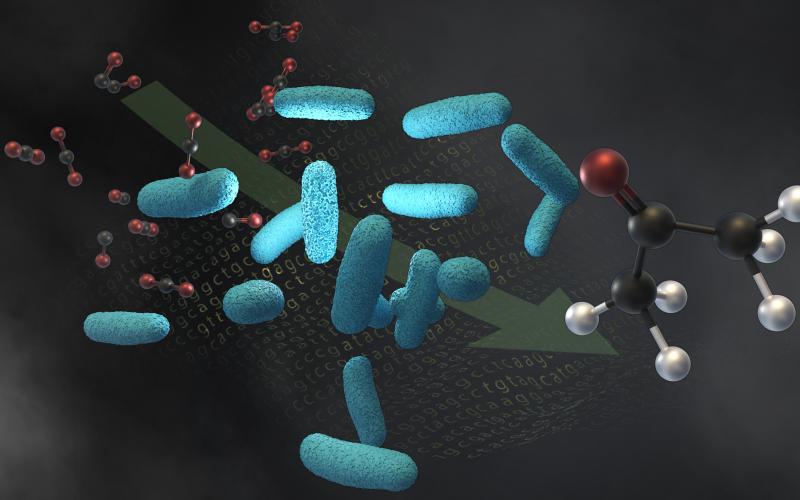

Researchers used technology from LanzaTech to make a new process that turns waste gases, like emissions from heavy industry or syngas made from biomass, into either acetone or IPA. They used an engineered bacterium called Clostridium autoethanogenum, or C. auto.

Scaling up technology

Scaling up this new technology is what LanzaTech is doing now. It can be added to their existing systems and used around the world. The research started at LanzaTech, where scientists had already made a process that can make ethanol, a common biofuel, out of carbon dioxide emissions. They used strains of C. auto that can make ethanol. Trying to figure out which enzymes were best for making acetone and IPA and how to make microbial strains that were efficient and made a lot of chemicals was a difficult scientific problem.

The scientists used a three-pronged approach that included new ideas in pathway screening, strain optimization, and process development to make their work better. As a first step, LanzaTech looked at more than 300 strains to see if they had enzymes that could be used in the making of acetone and IPA. Afterward, the scientists built the largest combinatorial DNA library ever for this type of microbe. They were able to find enzyme variants that made acetone better. Cell-free prototyping was used by Northwestern University, and advanced modeling and molecular analysis were done by LanzaTech and ORNL.

Making byproducts

These two studies, proteomics and metabolomics, give a molecular-level look at which chemicals a microbe is using and making and how it does this. When microbes eat or break down the things they need to live, they make byproducts. For scientists who are trying to get microbes to make certain things, these byproducts are bottlenecks.

ORNL scientists found that the microbe C. auto was making a lot of the compound 3-hydroxybutyrate, which would need to be treated later and make the process more expensive. This substance is in the middle of a very important metabolic process. It can move carbon in many different ways.

This project was made possible by the help of LanzaTech, which helped with the strain and process development, as well as genome-scale modeling, life cycle analysis of acetone, and pilot runs. Funding for the cell-free prototyping and ‘omics analyses was given to them by DOE’s Office of Science. There is a user facility called the Joint Genome Institute that helps people who want to do DNA sequencing.