Germany/USA – HeidelbergCement’s U.S. subsidiary Lehigh Hanson and Silicon Valley-based materials technology firm Fortera have announced an agreement to introduce a new method of carbon capture and utilization (CCU) technology at Lehigh’s Redding California Cement plant, with an estimated 60% reduction of CO2 emissions per ton of output.

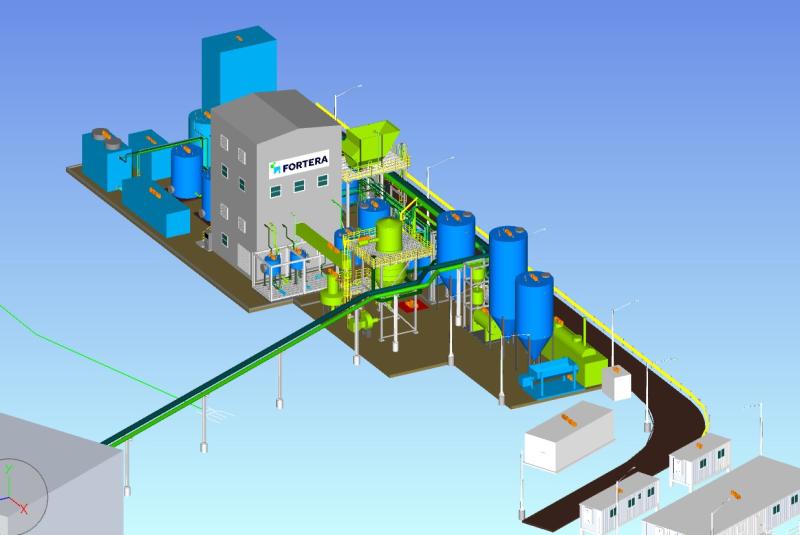

Both partners will build and run a small commercial plant where CO2 will be collected from the furnace exhaust and refined into cement material. The finished product will be ideal for use as a modern low-carbon SCM (Supplementary Cementitious Material) in the manufacture of high-quality concrete with a smaller CO2 footprint.

ReCarbTM

The commodity created by the latest carbon capture process at the Redding plant would be the first cement material commercially manufactured from CO2 collected directly from the cement furnace. Fortera’s patented recarbonation (ReCarbTM) process operates by tapping into existing feedstock and plant machinery, while production continues from the quarry to the furnace as normal. Instead of emitting CO2, the exhaust of the kiln is trapped and mineralized into a cement.