In Ludwigshafen chemical giant BASF is building a pilot installation for the pyrolysis of methane. Besides hydrogen, the process does not produce CO2, but valuable solid carbon from natural gas or biogas. Next year the pilot installation will be put into operation. After 2025 commercial upscaling may follow.

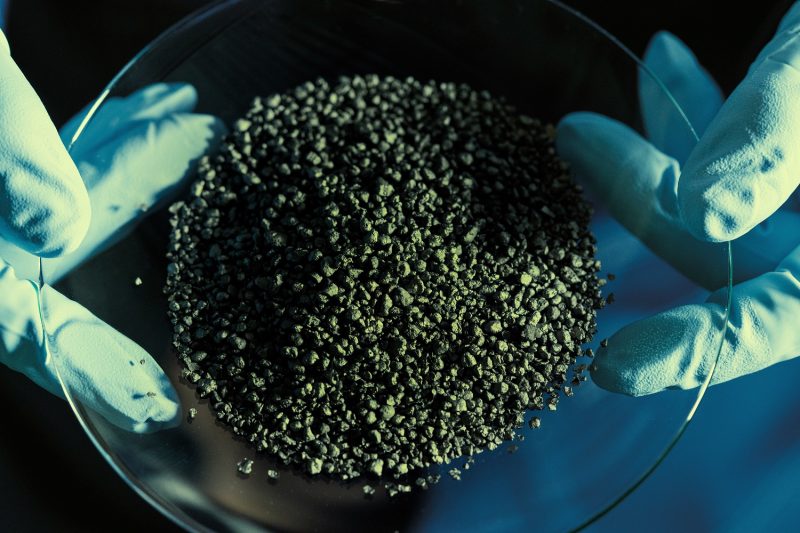

A relatively underexposed and clean alternative for the production of hydrogen is methane pyrolysis, or the turquoise route. In this technology, for example, methane is split at a high temperature into hydrogen and pure carbon in a molten metal alloy. Without the formation of carbon dioxide. In addition to these avoided emissions, extra value is created with the usable carbon. The applications are diverse. For example, additive for steel, filler in car tires, graphite, dye and soil conditioner. Read more about turquoise hydrogen here.

Test installation

Chemistry giant BASF announced two years ago that she is seriously investigating the option of methane pyrolysis. Together with, among others, gas producer Linde, steel company Thyssenkrupp and several German research institutes.

For BASF, it is one of the group’s intended routes for CO2-neutral growth over the coming decades. According to the chemical group, its variant uses about a quarter more energy than traditional steam methane reforming. However, the green, electrochemical route requires a tenfold increase, according to researchers of the group. BASF is now preparing the next steps in the research. The first pilot plants are to be built in a few years’ time. With the construction of a pilot plant in Ludwigshafen, the chemical company seems on schedule to scale up commercially just after 2025.